We provide services with more than 250 product types and nearly 3000 tons of constantly renewed steel stock, which we supply from over 60 steel manufacturer, which are leaders in their field which in 12 different countries, especially in Turkey and Europe

Powerful Stock

Our Stock Material’s Dimensions;

| Shape | Production | Section (mm) | Length (mm) |

| Round | Cold Drawn | Ø 5-80 | 3000-6000 |

| Hot Rolled | Ø 15-350 | 2000-7000 | |

| Forged | Ø 80-1000 | 2000-7000 | |

| Wire Rod | Ø 5-40 | - | |

| Hexagon | Hot Rolled | 15-75 | 3000-6000 |

| Cold Drawn | 5-70 | 3000-6000 | |

| Sheet | Hot Rolled | 5-20 x 100-2000 | 1000-6000 |

| Cold Drawn | 0,50-10 x 20x1000 | 1000-6000 | |

|

Square |

Hot Rolled | 8x8 - 800x800 | 2000-6000 |

| Cold Drawn | 5x5 - 100x100 | 3000-6000 | |

| Flat | Hot Rolled | 5-100 x 100-2000 | 3000-6000 |

| Cold Drawn | 5-100 x 100-1000 | 3000-6000 | |

| Block | Forged | 80-800 x 100-1000 | 1000-6000 |

Serial Cutting

We offer cutting services to the extent our clients request. Our expert staff; With our horizontal and vertical wide cutting track, meticulously prepares the materials you need and labels them in a way that will not cause any confusion in your facility.

Cutting Dimensions;

| Shape | Thickness (mm) | Width (mm) | Length (mm) |

| Round | between 5.00 - 1000 mm | max 12.000 mm | |

| Sheet | between 0.5 - 10 mm | between 10 - 2000 mm | max 12.000 mm |

| Flat | between 10 - 800 mm | between 10 - 2000 mm | max 12.000 mm |

Turning

In line with the general service concept, we always offer the best to our customers. Even if the round / diameter material you need is not in stock, with our turning machine; We deliver the intermediate dimensions between 50 - 600 mm by easily peeling them to the desired size.

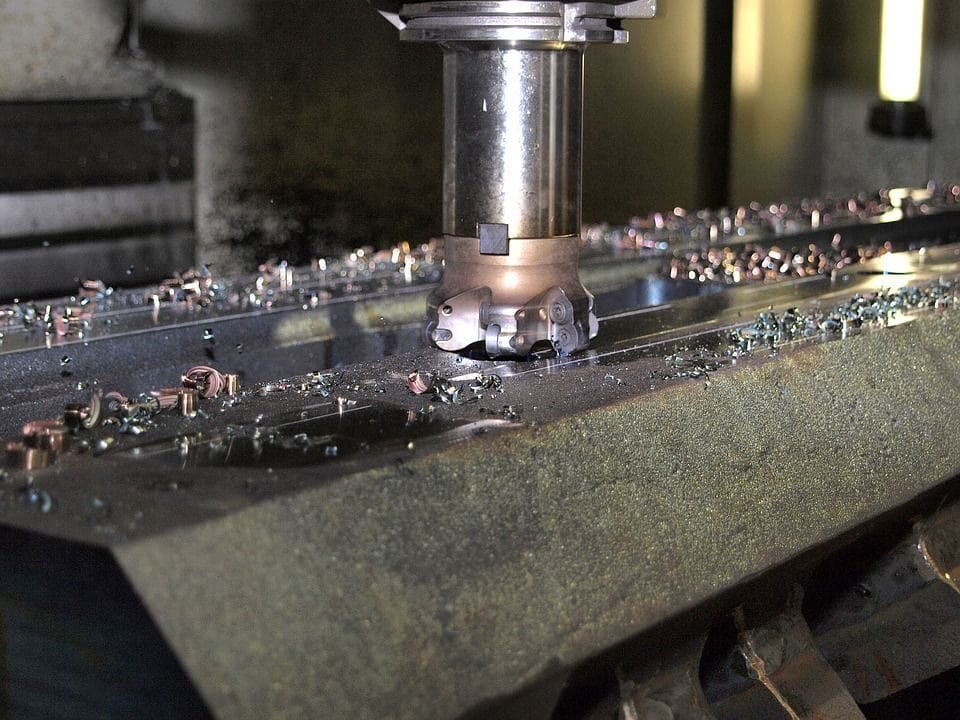

Milling

With the experience of being in this sector for many years, by analyzing the problems experienced in the supply of materials, It is one of our priorities to be able to provide the exact size you need by milling square, flat, block products between 10 - 300 mm thickness 100 - 1000 mm width and maximum 5000 mm length, thanks to our milling machine in our structure.

Special Packaging

With the idea of "Packaging is the dress of the product", we serve with special packaging options that meet the demands of our customers.

Fast Shipping

We know that the time from order confirmation to material delivery is very valuable for you. For this reason, with our international shipping portfolio, we have the power to make fast shipments to anywhere in the world at any time.

Special Production

With more than 60 manufacturers with whom we have an annual agreement, we produce and supply the materials with chemical analysis and mechanical values you need as soon as possible.

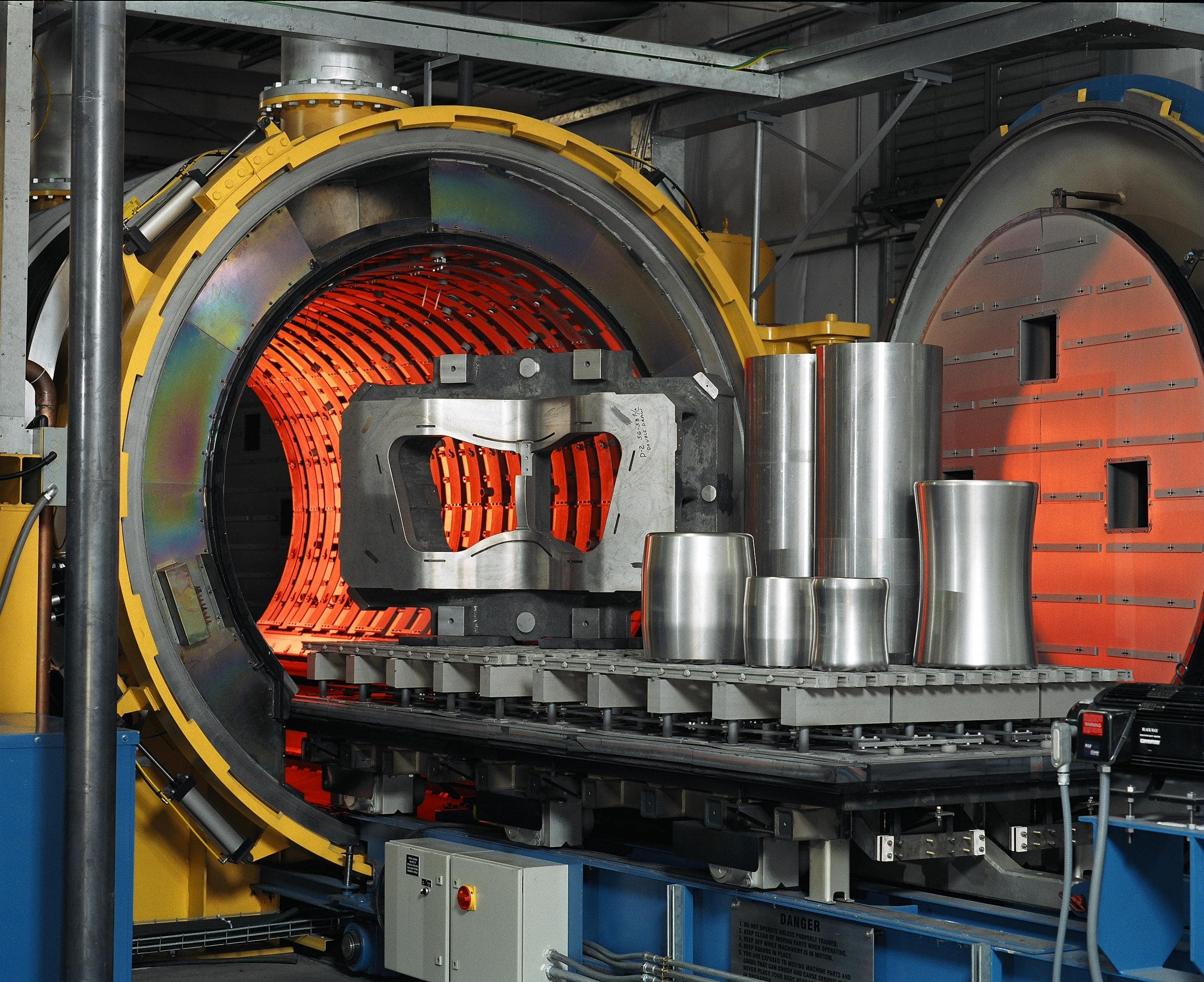

Heat Treatment

We see steel and heat treatment as a whole. Material performance is directly proportional to heat treatment quality. Our engineers in our Partner Heat treatment company create batchs according to the quality, size and desired hardness of your part. After all heat treatment applications are recorded, they are served with a certification and performance report.

Our Heat Treatment Applications;

Our Heat Treatment Applications;

- Tempering

- Oxidation

- Carburization

- Nitration

- Induction

- Stress relieving

- Normalization Annealing

- Aging

Laboratory

"The road to quality passes through the right tests".

As we question the quality of every steel that enters our stock, we offer our state of the art laboratory to your service.

As we question the quality of every steel that enters our stock, we offer our state of the art laboratory to your service.

- Kimyasal Analiz

- Chemical analysis

- Hardness Measurement

- Microstructure Analysis

- Ultrasonic Test

- Tensile Test

- Impact Test

Etc. For all your requests, please contact us at "quality@saldametal.com" e-mail address.

Technical Support

We provide engineering services in your projects with our strong engineer staff who are experts in their fields and our experience in the sector. We are a solution partner in material selection, design, processing, application techniques and heat treatment. We offer you alternative material choices that will make a difference in mass production and product quality, in case of problems arising from the wrong material choice.