Material Description: It is plastic mold steel that is delivered in pre-hardened condition. 1.2312 is preferred for better machinability.

Chemical composition:

(Typical analysis in %)

| C | Si | Mn | P | S | Cr | Mo |

| 0,35 – 0,45 | 0,20 - 0,40 | 1,30 - 1,60 | ≤ 0,03 | ≤ 0,03 | 1,80 - 2,10 | 0,15 - 0,25 |

Steel properties: It has high toughness and good wear resistance, shines better and shows higher abrasion resistance than 1.2312, does not require heat treatment, can be easily processed and polished, can be nitrided to increase wear resistance, Surface etching, welding and patterning, chrome and nickel plating suitable.

Applications: Plastic injection molds for medium and large sizes up to 400 mm, cases, holders and fittings of the pressure casting industry and plastic injection molds, sleeves of extruders, stamping molds for rubber type rubber products, plastic molds for the automotive and food industry, and high liquid pressure molds for forming metals under.

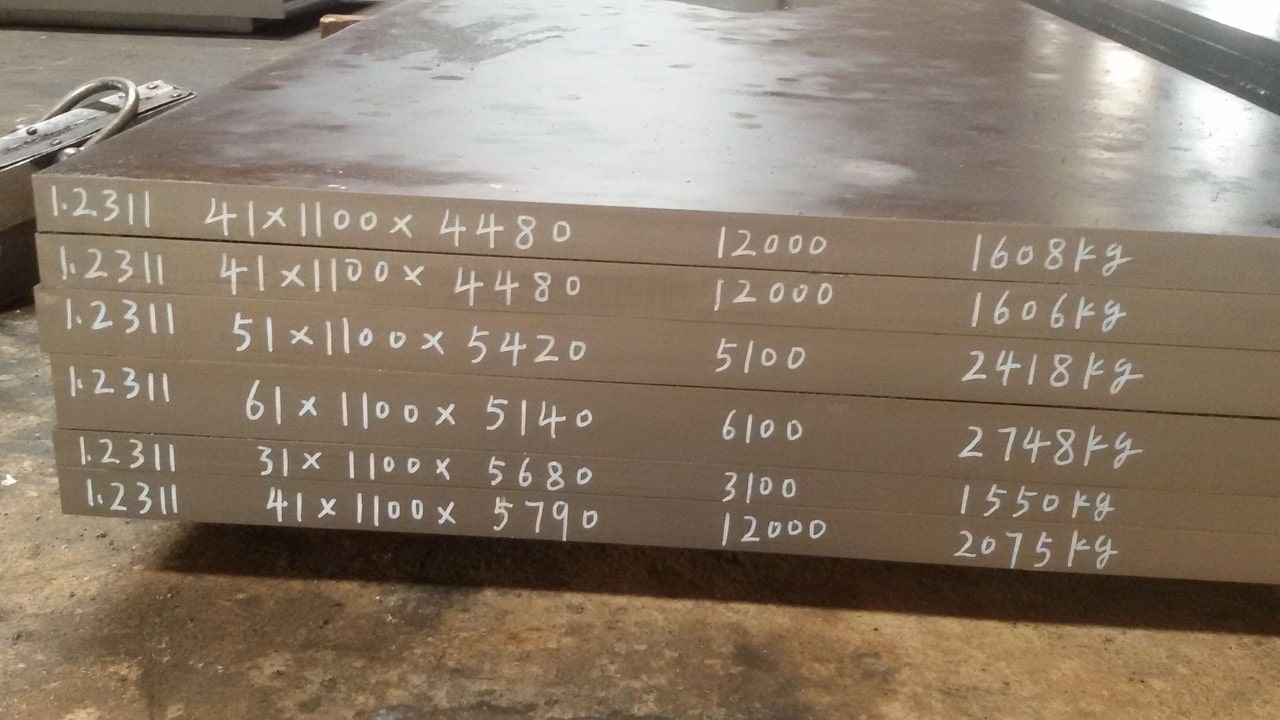

Condition of delivery: Pre-hardened, 280-320 HB